Power Line Break Equipment Shop

Shop Now

Shop Now

Shop Now

Shop Now

Most Sold Products

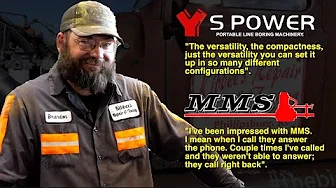

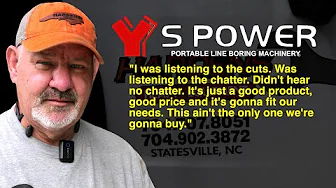

TESTIMONIALS

News & Events

-

Posted: July 12, 2024Categories: Press ReleaseRead more »Mobile Machine Source North America is proud to announce the addition of the JLP-230 Portable Journal Lathe to its product lineup for the North American market. Designed for precision shaft restoration, the JLP-230 is engineered to meet the rigorous demands of industries requiring accurate shaft repair and maintenance...

-

Posted: June 30, 2024Categories: Press ReleaseRead more »

Orlando, FL — Mobile Machine Source North America is excited to announce its participation in FABTECH 2024, North America’s largest event dedicated to metal forming, fabricating, welding, and finishing. The event will take place at the Orange County Convention Center in Orlando, Florida, from October 15th to 17th, where industry professionals and experts will gather to explore the latest innovations...

Product Demonstration videos

1 FAQS

Yes. The Spower Line Boring and Bore Welding machine is a multifunction automated weld positioner. Your kit includes an adapter to convert the Spower European style lead to Miller, Lincoln, and other popular brands of wire feeders or shop machines. Please contact us if you need help determining the brand or style of adapter you need.

Yes. The Spower line boring and bore welding machine has a 1 year factory backed warranty.

Yes. Mobile Machine Source NA has a complete inventory of parts to repair or replace damaged or defective parts.

Our immediate concern is always to get you back up and running. If we can’t resolve the issue by trouble shooting with you over the phone we ship the replacement part(s) to you the same day, by UPS Next Day Air absolutely free. That means you will receive the new part(s) by the end of the following day and some cases by noon. The defective or broken part(s) is automatically scheduled for pick up 2-3 days later. Place the broken or defective part in the same box the new part arrived in. Use the same packing material to prevent the return item from damage in transit. Apply the prepaid UPS return label, and leave the package where your UPS driver will see it. That’s it!

The bore welder is a multifunction automated weld positioner. It can be fully operated using the handheld remote or by the display control panel. The bore welder can perform continuous weld, skip weld, sector weld, and reverse weld functions. Setting the bore diameter automatically adjust the rotational speed and feed rate to lay a nice bead. Bore diameter can be adjusted for optimal results.

Yes. We are happy to teach you everything we know about line boring and how to get the most out of your investment. Whether you need a crash course in setting up your machine or want a multi-day in depth experience, Mobile Machine Source offers customers free hands on training at our Florida location.

Unlike hand welding, the automated bore welder will operate for extended periods of time, without interruption. When using 0.035 wire a small to medium hole can take 15-30 minutes of continuous welding. Larger holes can take well over an hour. Therefore, it is recommended that for 0.035 wire, you have a welding machine with a 100% duty cycle at 125-150 Amps. You may contact us to discuss your specific needs. We are happy to help.

Call or text 888-401-1021anytime. If it's after hours, and you leave us a message explaining your problem we'll do our best to get you back up and running. Mobile Machine Source North America is the exclusive factory direct store for Spower. All warranty claims are handled for you personally by our dedicated staff.

Every set up is different and requires some fine tuning to achieve the results you want. The recommended wire size is 0.035. Bore welding should be done with a constant voltage (CV) setting. For portable set ups with wire feeders we recommend that your voltage be set at 19-21 volts with a wire speed of 210-250 ipm. Most shop machines can be set at 18 volts with a wire speed of 200 ipm.

Yes. We ship to Canada and to the other 21 independent countries in North America

Financing Available

Financing Available